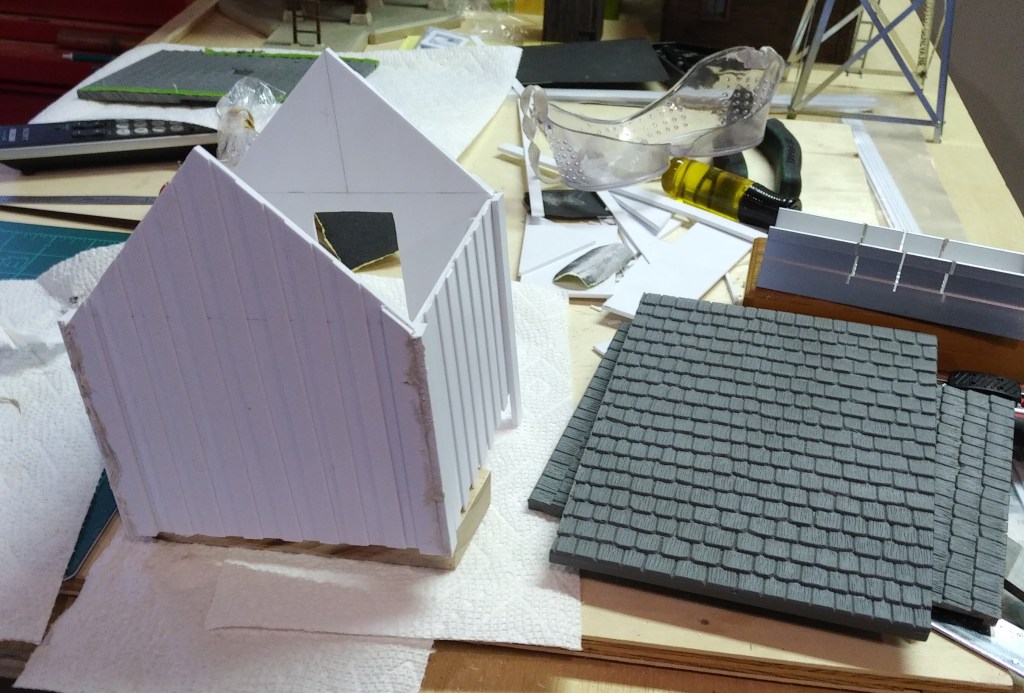

I decided to design my own pumphouse to support my windmill using some styrene I had on hand, part of a Piko shingle roof, and a door from Stoneworks. I think it turned out pretty well for my first custom building.

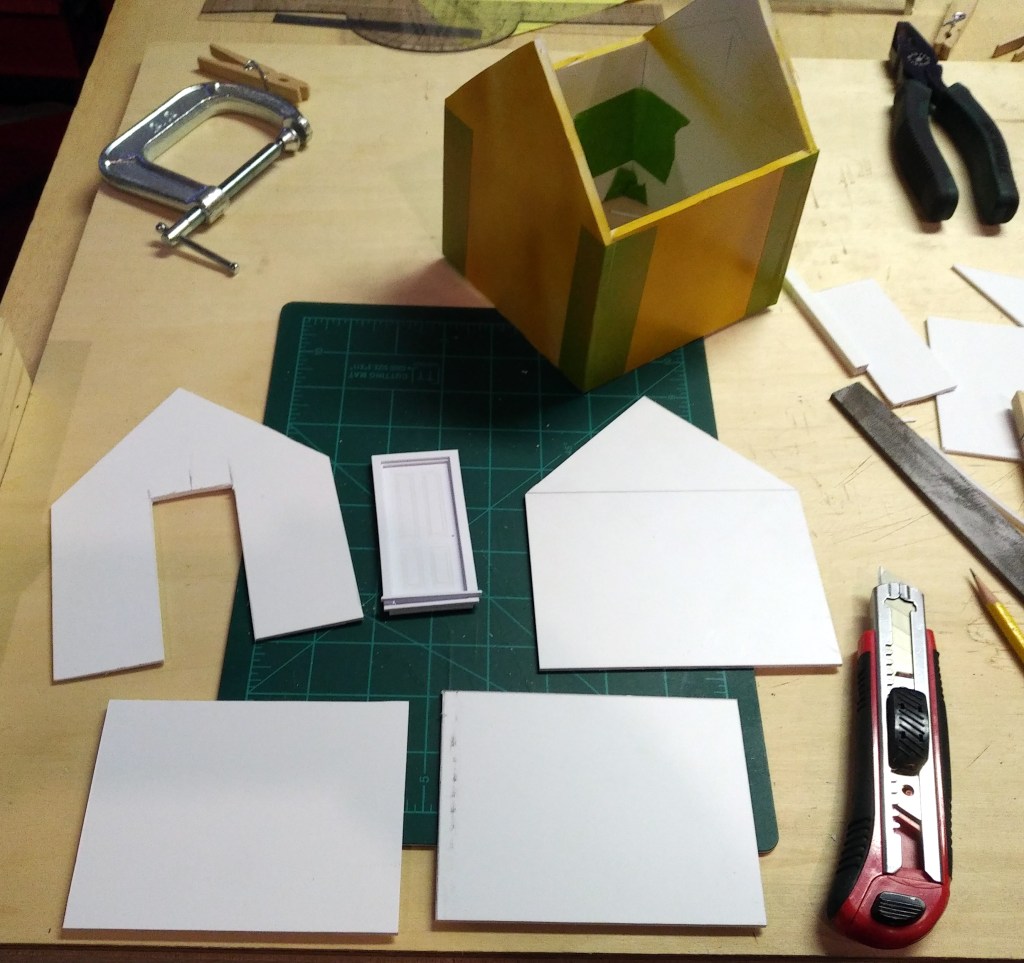

The exterior is simply a thicker sheet of styrene with battens of thinner styrene glued and plastic welded over the top. I assembled the door first and used that to create a mockup using poster board to determine the size of the structure. The roof I just snipped out of the larger Piko shingle roof on my miter saw, covering the peak with some 45-degree styrene corners that came with some other items I ordered from Stoneworks.

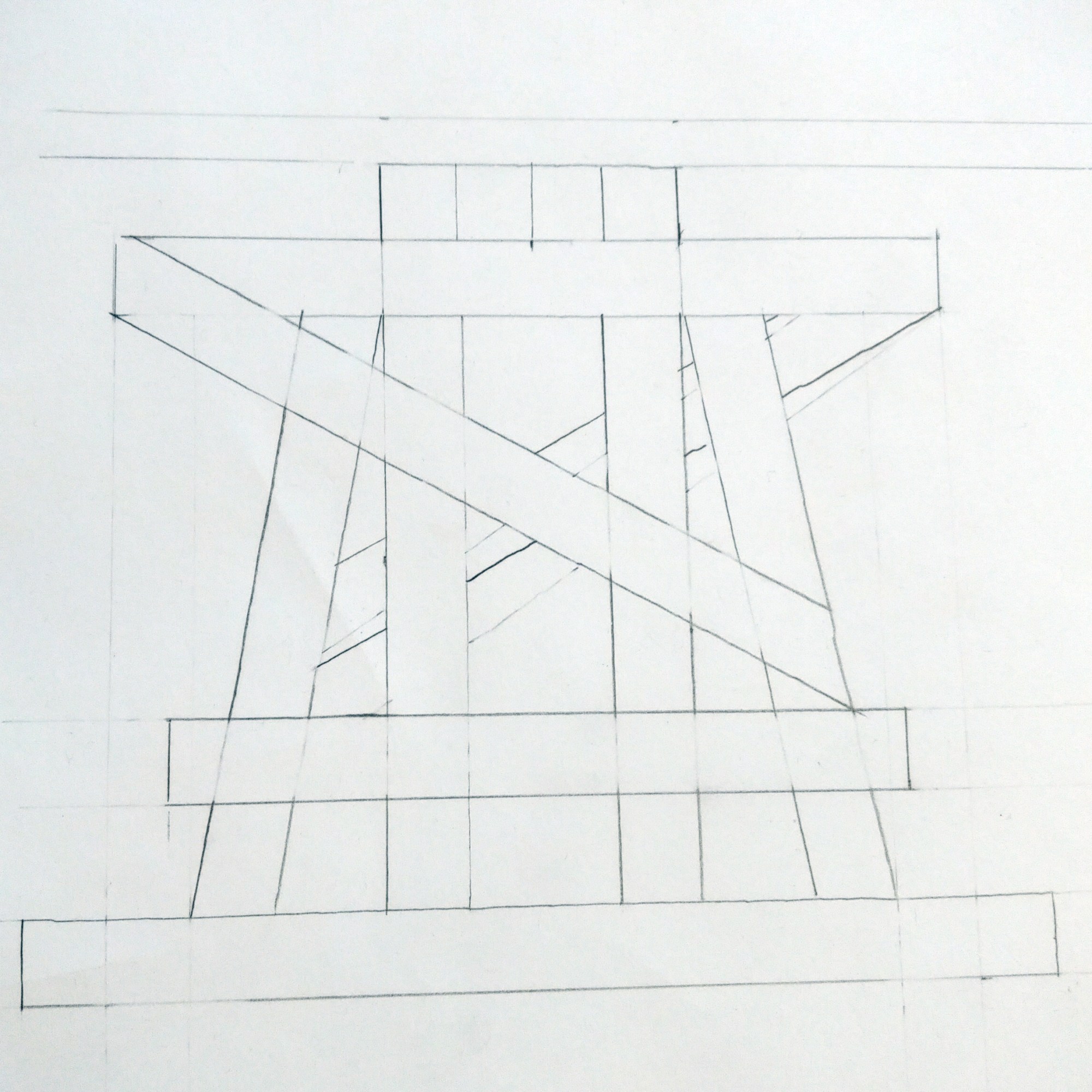

Although I didn’t get a picture, I used blocks of 3/4” PVC board to create a solid core that I glued the roof onto. That separate solid core slides down into the exterior frame, and then silicone to help hold it together. A hidden solid base underneath unifies it all, with screws inserted behind the removable door and up from the bottom. To hopefully hold it in place in high winds, I added strapping to the bottom and pounded a large spike into the ground on each side. We’ll see how well it holds up. My hope was to be able to create a solid structure that I could dissemble when the time comes to repaint it or if I should choose to add further details.